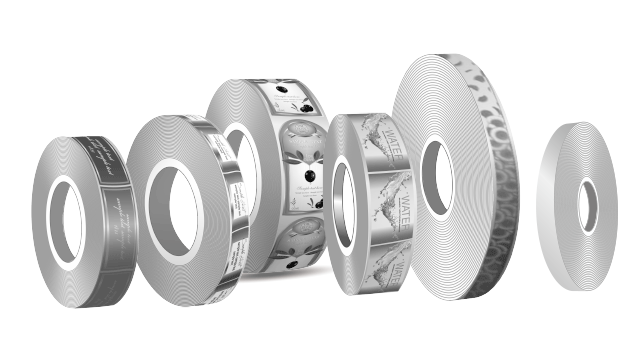

- Materials

-

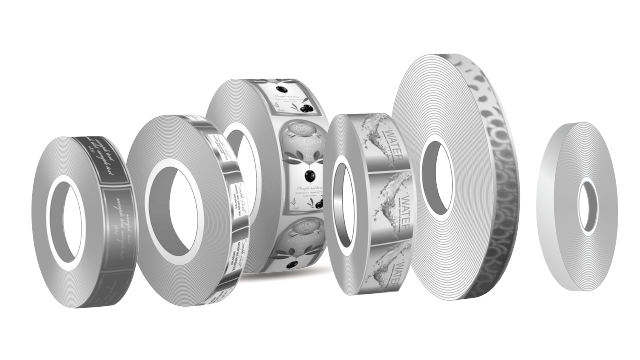

- Laminated films 40-150μ; OPP 30-150μ; CPP 30-150μ; PVC (Soft), 30-150μ; PET 30-80μ; Meltblown Nonwoven Fabric

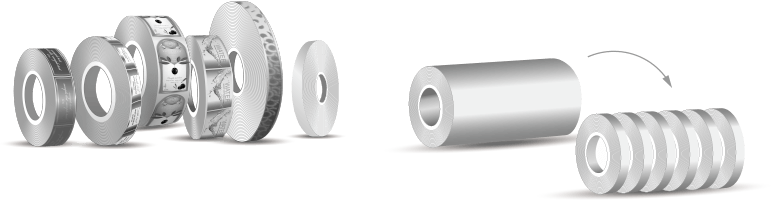

- Rewinding Type

-

- Diff erential center rewinding with duplex rewind shafts.

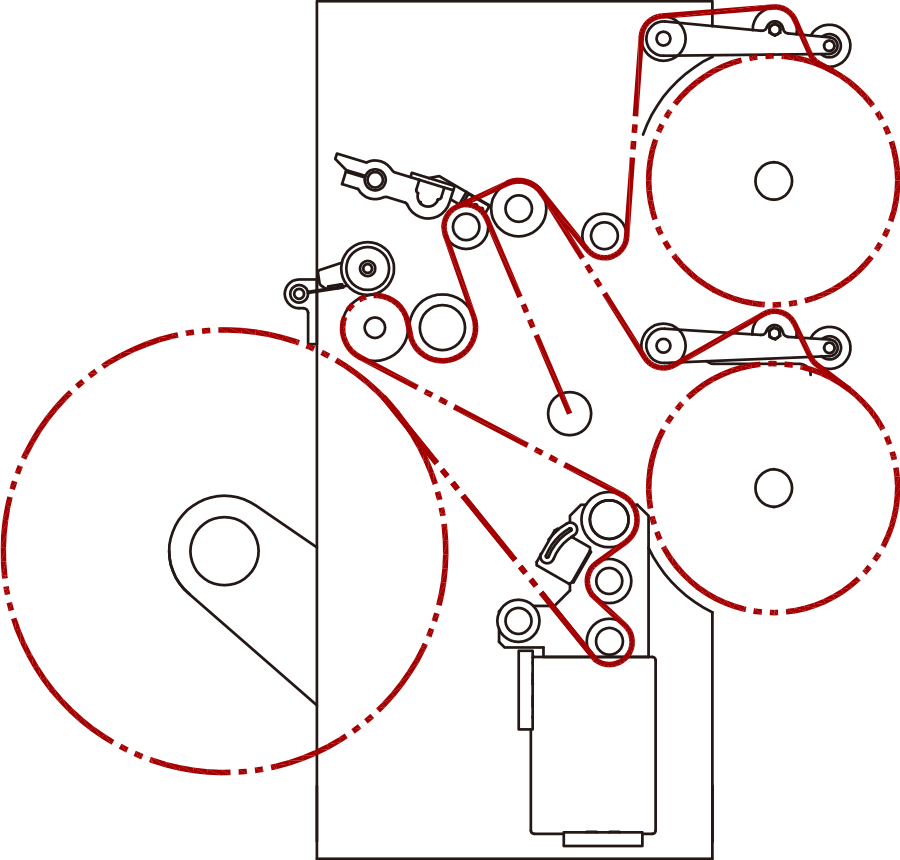

- Unwinding Section

-

- Shaft less unwinding stand (Motorised left / right movement) with mechanical chuck.

- Equipped with digital type line position control (LPC) to ensure accurate slitting position.

- Slitting Section

-

- Equipped with razor cutter and cutting in the air.

- Equipped with grooved roller for razor blades.

- Equipped with blower and expulsion tube.

- Rewinding Section

-

- Cantilevered type mechanical rewinding shafts for easy operation.

- Equipped with ball type friction rings, which not only can facilitate the concentricity of the paper cores and finish rolls, but also can make unloading easier without causing paper dust.

- Equipped with automatic tension controlling system and load-cells. The actual tension is digitally displayed, increasing the tension control precision with minimal operation e ffort.

- Static eliminated brush equipped.

- Lay-on roller pneumatic pressure control system.

- Unloading device.

| Model No. | SLV-T130F | |

|---|---|---|

| Min. & Max. parent web width | 650~1300 mm | |

| Max. parent web diame | 800 mm | |

| thickness range | 35~150 µ (Depends on various materials' conditions) | |

| Unwind / rewind core I.D. | 3” or 6" | |

| Max. rewind diameter | 450 mm | |

| Min. slit width | 50~650 mm (Depends on various materials' conditions) | |

| Max. machine speed | 300 M/min. | |

|

Installation information (For 1200mm standard machine) |

Net weight | 2600kg |

| Area required | L 1800 x W4000 x H1600 (mm) | |

| Power | As request | |

Gravure and flexographic printing

Digital printing