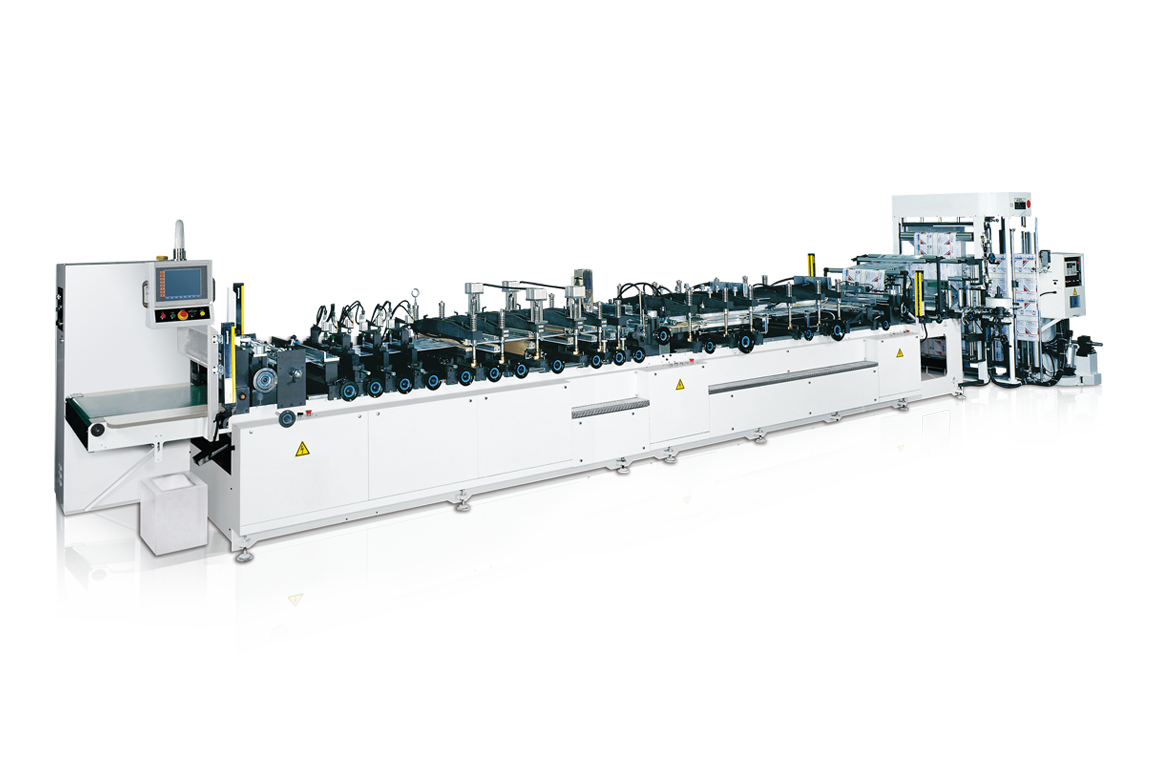

- Application & Materials

-

- Sealable laminated film, thickness 40-150μ

- Main Drive & Feeding Motor

-

- Main drive servo motor with driver provide accurate sealing time control, suitable for constant sealing time control system.

- Feeding Motor

-

- Equipped with two sets of servo motors and drivers, which can raise the production speed and provide accurate bag length control.

- Unwinding Section

-

- Horizontal type unwind stand / Swing-out/Lift-up type mechanical shaft with 3" adapters makes loading and unloading more convenient.

- Equipped with Automatic Tension Controller (diameter calculating type), provide constant and stable web tension control.

- Equipped with Line/Edge Position Controller (LPC), provide accurate bag sealing and trimming position.

- Upgraded dancer-roller provides stable tension for films before entering the bag making section.

- Bag Making

-

- Four-lanes operation for making 3-side-seal bags.

- Longitudinal double sealing device and cooling devices provides each sealing area could be sealed twice by different sealing temperature. Suitable for high-speed production and ensure the bag sealing quality.

- Equipped with skip operation system, the maximum bag-length could be extended. (skip-times: as request).

- Equipped with automatic lift-up mechanism to lift up the upper sealing stands and bars to avoid overheating the material when the machine stops.

- The design of safety cutter provides extra safety for the operator.

- Maintenance

-

- Equipped with covered bearing, which is unnecessary for lubrication, prolong the parts life and makes maintenance easier, faster and cleaner.

- Computer Control Operation with Touch-Screen

-

- Maintain a constant sealing time, which may largely reduce test-run scraps. When the machine speed is changed, it is not necessary to adjust temperature of the heater.

- Touch-screen makes operation easier and faster.

- Built-in Sealing Temperature Controller.

- Auto alarm/Stop available for abnormal condition.

- Alarm messages are displayed on the screen.

- Modem interface available for remote maintenance.

- Operation and maintenance procedures and parameters are memorized in the computer control system for easy setup or review.

- Data base for saving 100 sets of working parameters.

- Optional Accessories

-

- Unwind 3"/6" airshaft.

- Hydraulic loading device (in unwind section)

- 6" air chuck

- Vertical/horizontal 2nd unwind stand

- Various puncher

- Conveyer

- Round corner cutter

- Trim rewinder

- Bottom symmetrical folding stand

| Model No. | ABM-54S | ABM-64S | ABM-74S | |

|---|---|---|---|---|

| Max. Parent Web Width | 400 ~ 1000 mm | 400 ~ 1200 mm | 400 ~ 1400 mm | |

| Max. Parent Web Diameter | 650 / 800 mm | 650 / 800 mm | 650 / 800 mm | |

| Max. Bag Width | 500 mm | 600 mm | 700 mm | |

| Max. Bag Length | 500 mm | 500 mm | 500 mm | |

| Max. Machine Speed | 180 Cuts / min. | 180 Cuts / min. | 180 Cuts / min. | |

|

Installation information (Standard specificatio) |

Net weight | 4700 kg | 4800 kg | 5000 kg |

| Area required | L 12141 x W 5229 x H 1795 (mm) | L 12462 x W 5149 x H 1980 (mm) | L 12550 x W 5620 x H 2195 (mm) | |

| Power | 380V /31KW / 65A | 380V / 33KW / 67A | 380V / 35KW / 69A | |

| Water | 15 - 20 ℃ | 15 - 20 ℃ | 15 - 20 ℃ | |

| Air | 6 kg / cm3 | 6 kg / cm3 | 6 kg / cm3 | |

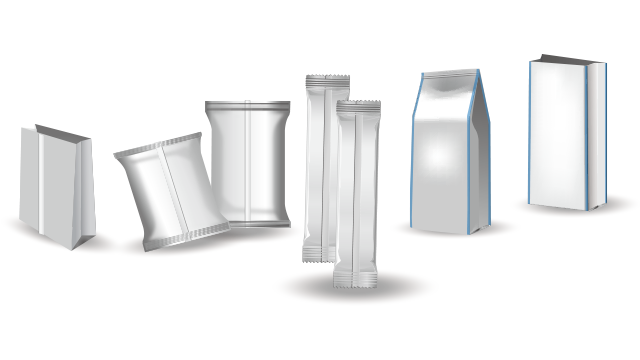

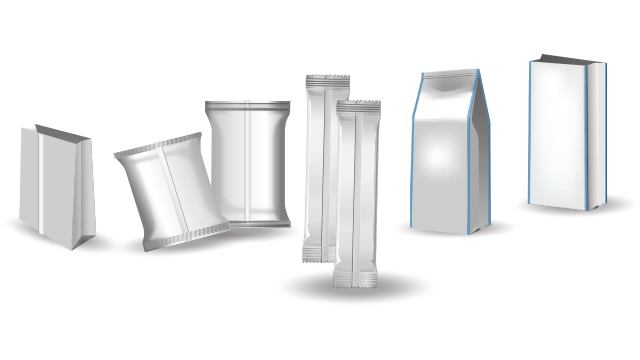

Food

Steam

Frozen

Rice

Clothes

Mask

Liquid

Antistatic